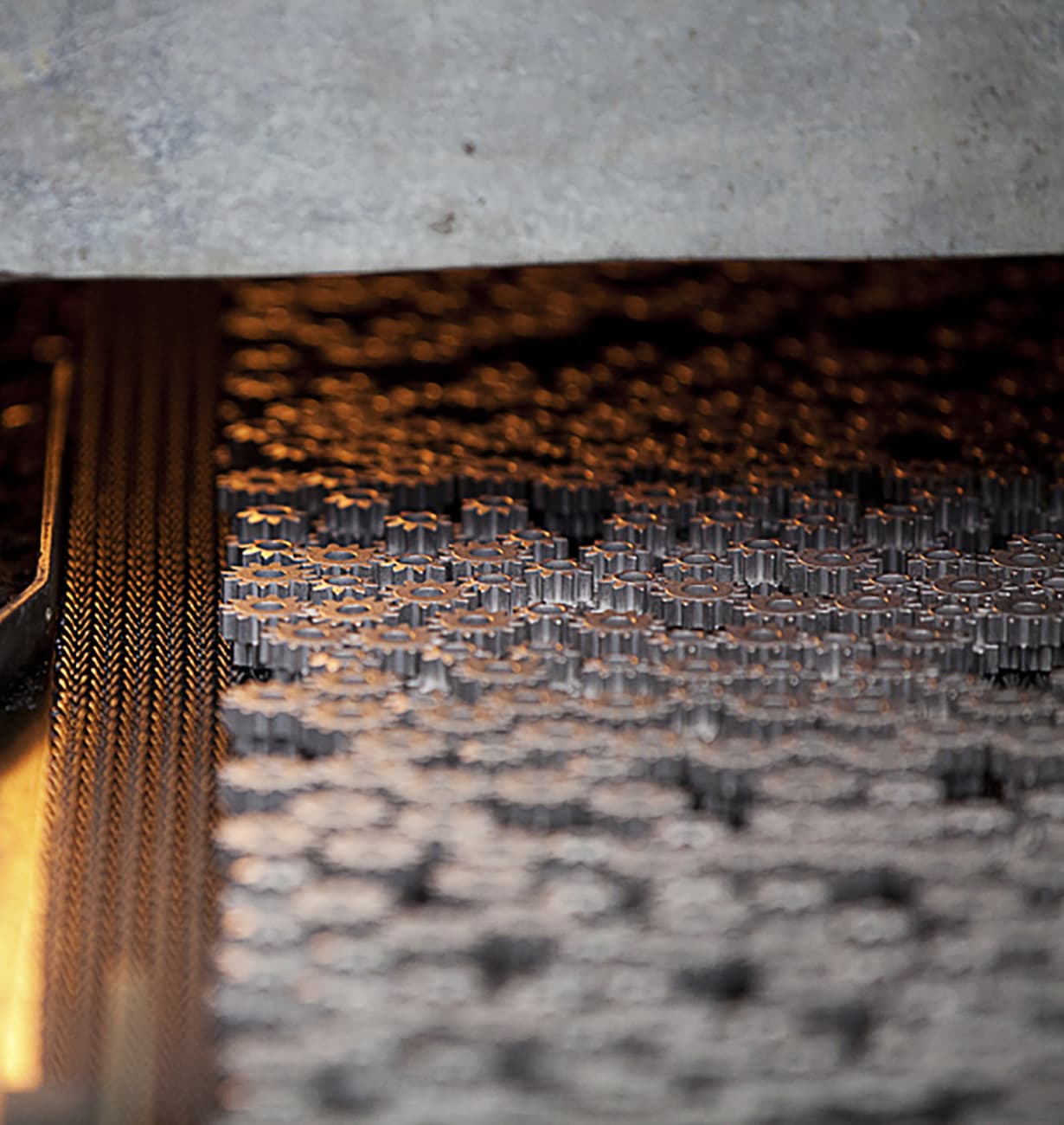

SINTERING IS THE PROCESS OF USING HEAT TO TURN POWDERED SUBSTANCES INTO SOLIDS WITHOUT ACTUALLY MELTING THE MATERIAL.

Benefits of sintered powder metallurgy (PM):

- Cost effective

- Provides excellent reproducibility and repeatability

- Many features can be formed in tooling, thus eliminating or minimizing machining

- Very high material to yield ratio

- Wide variety of alloy systems and materials are available

- Long term performance reliability

- Excellent surface finishes

- Energy efficient and environmentally friendly

- Sustainability